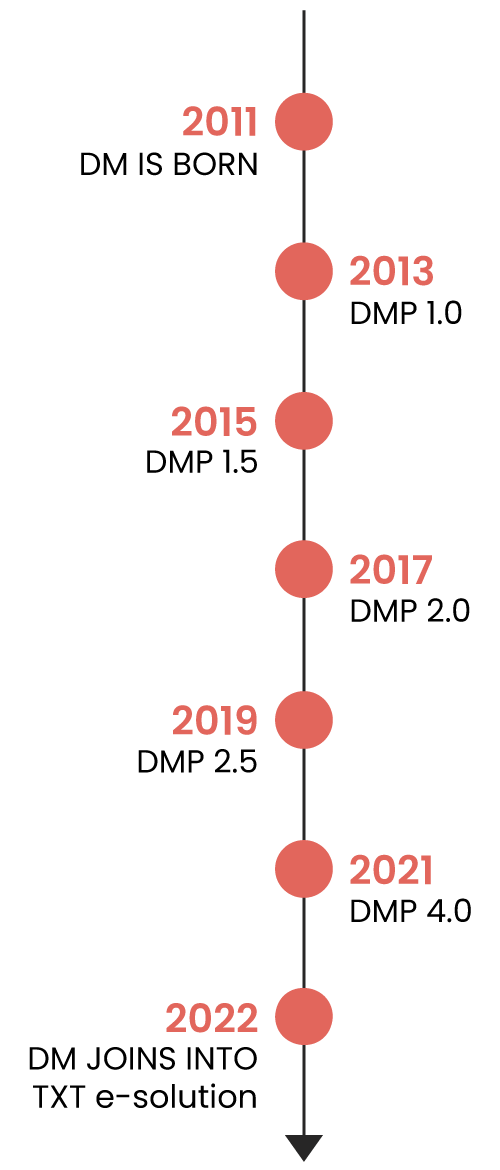

DM Management & Consulting was founded in 2011 when the three partners, Stefano, Luca and Davide, decided to transform the previous business consulting activity in a MES application platform, Web Native.

The introduction to the market of the first version of the MES platform DMP takes place in 2013 anticipating the needs of the current market.

In 2019, after only 6 years, the version 2.5 was introduced. DMP still tries to anticipate the times with innovative features in the graphics, content and new technologies.

In February 2021, DM has completed 10 years of activity. It was born at a time when there was still a certain scepticism about implementing innovative technologies. Especially in the production departments of industries. DM has been able to ride the wave of the Industry 4.0 plan.

He held his balance during the pandemic.

Today we continue to grow because we go ahead with the same dedication and courage that led us to start the company in 2011.

In these 10 years, we have realized projects in important national and multinational companies.

In 2022, DM joins into IIoT Smart Solution portfolio of TXT Group S.p.A. This operation allows to strengthen the market positioning of the MES/MOM platform DMP, which has released version 4.0.

What have we learned over these years?

It’s essential to cultivate human relations, from customer care to establishing new partnerships that consolidate the presence of DM in wider markets both national and international.

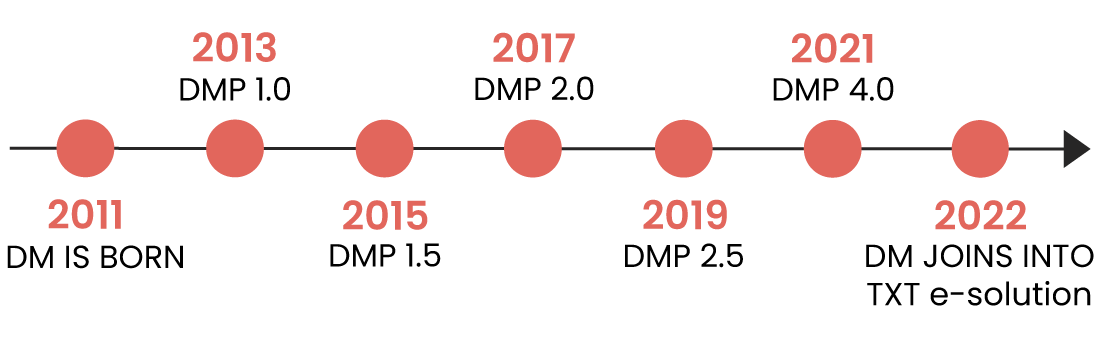

DM Management & Consulting was founded in 2011 when the three partners, Stefano, Luca and Davide, decided to transform the previous business consulting activity in a MES application platform, Web Native.

The introduction to the market of the first version of the MES platform DMP takes place in 2013 anticipating the needs of the current market.

In 2019, after only 6 years, the version 2.5 was introduced. DMP still tries to anticipate the times with innovative features in the graphics, content and new technologies.

In February 2021, DM has completed 10 years of activity. It was born at a time when there was still a certain scepticism about implementing innovative technologies. Especially in the production departments of industries. DM has been able to ride the wave of the Industry 4.0 plan.

He held his balance during the pandemic.

Today we continue to grow because we go ahead with the same dedication and courage that led us to start the company in 2011.

In these 10 years, we have realized projects in important national and multinational companies.

In 2022, DM joins into IIoT Smart Solution portfolio of TXT Group S.p.A. This operation allows to strengthen the market positioning of the MES/MOM platform DMP, which has released version 4.0.

What have we learned over these years?

It’s essential to cultivate human relations, from customer care to establishing new partnerships that consolidate the presence of DM in wider markets both national and international.

DM Management & Consulting was founded in 2011 when the three partners, Stefano, Luca and Davide, decided to transform the previous business consulting activity in a MES application platform, Web Native.

The introduction to the market of the first version of the MES platform DMP takes place in 2013 anticipating the needs of the current market.

In 2019, after only 6 years, the version 2.5 was introduced. DMP still tries to anticipate the times with innovative features in the graphics, content and new technologies.

In February 2021, DM has completed 10 years of activity. It was born at a time when there was still a certain scepticism about implementing innovative technologies. Especially in the production departments of industries. DM has been able to ride the wave of the Industry 4.0 plan.

He held his balance during the pandemic.

Today we continue to grow because we go ahead with the same dedication and courage that led us to start the company in 2011.

In these 10 years, we have realized projects in important national and multinational companies.

In 2022, DM joins into IIoT Smart Solution portfolio of TXT Group S.p.A. This operation allows to strengthen the market positioning of the MES/MOM platform DMP, which has released version 4.0.

What have we learned over these years?

It’s essential to cultivate human relations, from customer care to establishing new partnerships that consolidate the presence of DM in wider markets both national and international.

Technological innovation, production culture and design propositions are the values in which we believe and which distinguish us as a company.

Our vision comes from our values: support and assist companies, step by step, to innovate by digitizing their production department.

With the term innovation we intend to achieve green goals, keeping up with the times, and anticipating the needs of customers, companies and factories.

We want to make easier the complex world of production. Facilitate every stage of production processes in order to eliminate and stem bottlenecks and inefficiencies.

Set our compass with the goals and our vision, our research and development team leads, annually, the analysis of the feedback and the implemented projects.

One of the areas in which we are focusing the recent projects is that of environmental sustainability which has become increasingly important for the digitalization of production processes.

In fact, in line with the industrial scenario and the increasing demand for sustainable production models, DM stands as a means by which companies reduce energy and waste, increase efficiency and achieve green results.

DM Management & Consulting® offers to the market innovative and constantly evolving digital solutions and services to support and accompany companies in the digitization of production.

Our product is the MES platform DMP© Intelligent Manufacturing that allows you to acquire, manage, analyze and provide information of all data generated by machines and operators.

The proposed solutions are designed to take advantage of the production capacity of each resource and to increase production efficiency through the monitoring of the OEE indices. Increasing attention is paid to maintenance, cost reduction, and fault management analysis.

The company’s digitization makes the need to acquire digital platforms that allow efficient use of machines more and more evident.

MES systems, although not new, have become increasingly strategic for companies engaged in the digitization of production processes.

Technological innovation, production culture and design propositions are the values in which we believe and which distinguish us as a company.

Our vision comes from our values: support and assist companies, step by step, to innovate by digitizing their production department.

With the term innovation we intend to achieve green goals, keeping up with the times, and anticipating the needs of customers, companies and factories.

We want to make easier the complex world of production. Facilitate every stage of production processes in order to eliminate and stem bottlenecks and inefficiencies.

Set our compass with the goals and our vision, our research and development team leads, annually, the analysis of the feedback and the implemented projects.

One of the areas in which we are focusing the recent projects is that of environmental sustainability which has become increasingly important for the digitalization of production processes.

In fact, in line with the industrial scenario and the increasing demand for sustainable production models, DM stands as a means by which companies reduce energy and waste, increase efficiency and achieve green results.

DM Management & Consulting® offers to the market innovative and constantly evolving digital solutions and services to support and accompany companies in the digitization of production.

Our product is the MES platform DMP© Intelligent Manufacturing that allows you to acquire, manage, analyze and provide information of all data generated by machines and operators.

The proposed solutions are designed to take advantage of the production capacity of each resource and to increase production efficiency through the monitoring of the OEE indices. Increasing attention is paid to maintenance, cost reduction, and fault management analysis.

The company’s digitization makes the need to acquire digital platforms that allow efficient use of machines more and more evident.

MES systems, although not new, have become increasingly strategic for companies engaged in the digitization of production processes.